Thứ ba, 10/06/2025 | 05:22 GMT+7

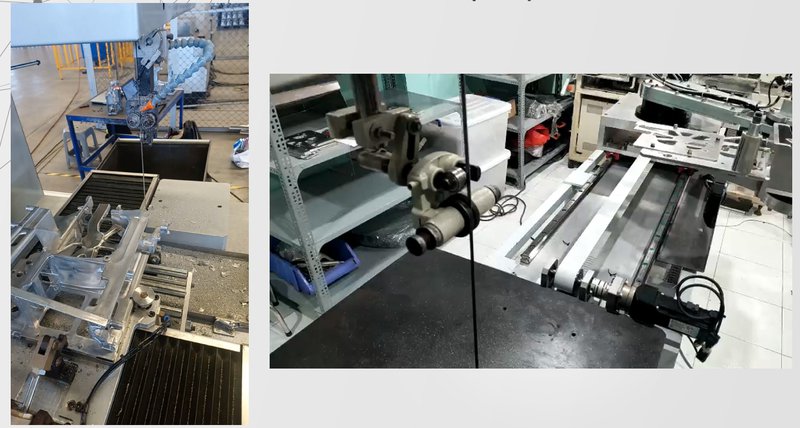

ABSTRACT The paper presents the results of the design and manufacture of the automatic band saw machine for cutting residue, havia casting products. The system consists of a jigsaw machine with a vertical movement saw blade incorporating a 2.5D workpiece moving table. The machines controller is built on the computer main board. The operating mode is programmed through the interface on the digital control panel and sends commands to the saw machine drives and moves the workpiece accordingly. The proposed solution for sewing machine frame trimming includes simulation of the workpiece trajectory determination to generate data to control the 2.5D machine table. Then use this data set to train the machine to move precisely in the actual trajectory. Therefore, cutting accuracy is enhanced on a configuration that is not as complicated as using a workpiece transfer robot. The machine has the following technical features: Cutting material: Aluminum, copper; Strokes (X Y): 400x400 mm; Maxừnum cutting thickness 20 mm (aluminum); Error position: ± 0.3 mm; Repeatability error: ± 0.2 mm; Machining error: ± 1 mm; Power: 4 kW; speed of machine table 1-8 m/ ph; Cutting angle: 270°. Equipment has been used effectively at Nhat Tinh Company (HCMC). Keywords: Automatic bavia cutting; CNC band saw machine. |

Đối với ngành da giày, các hiệp định thương mại tự do không chỉ mang lại cơ hội gia tăng xuất khẩu mà còn thúc đẩy sự đổi mới, chuyển đổi chuỗi cung ứng và cải thiện chất lượng sản phẩm để đáp ứng các tiêu chuẩn quốc tế.

04/06/2025