Thứ hai, 09/06/2025 | 16:59 GMT+7

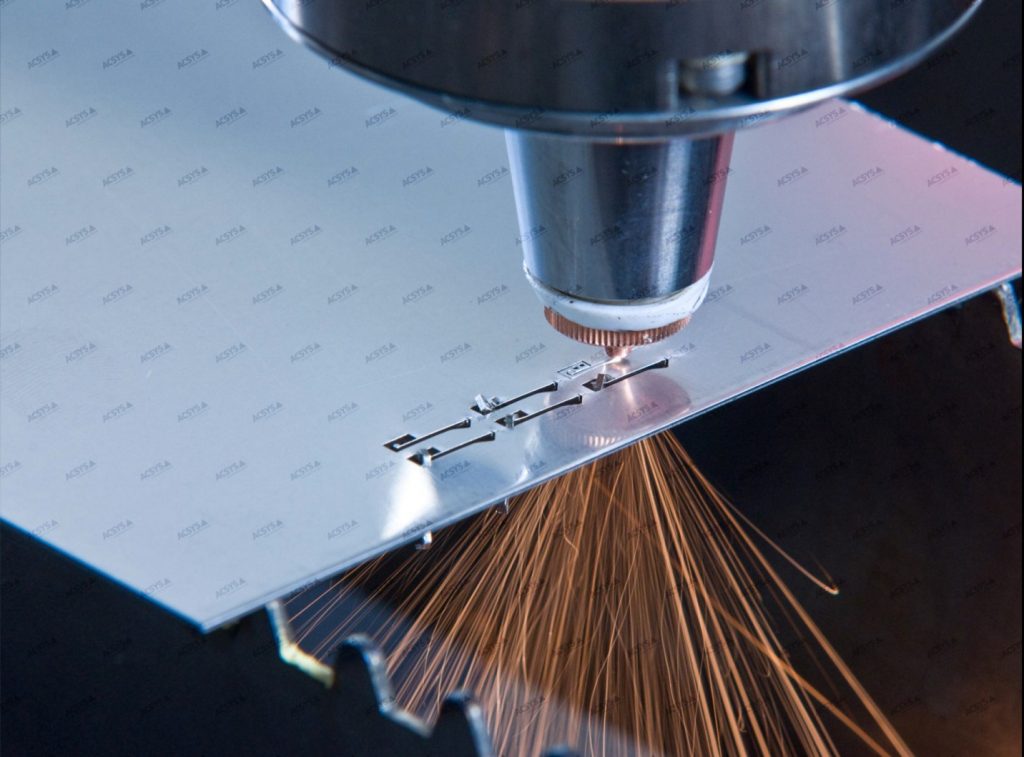

RESEARCH THE EFFECTS OF POWER LASER, CUTTING SPEED AND NOZZLE DIAMETER TO THE SURFACE ROUGHNESS IN LASER CUTTING OF SKD11 STEEL Abstract: Laser machining is a directly mechanical noncontact process between tools and workpiece; the possibility of splitting material based on the thermal effect is very suitable for advanced materials which are difficult to machine by traditional methods. The most important feature of laser cutting is the ability to generate highly concentrated thermal energy to perform high-speed machining with high precision, with a narrow cutting kerf, high-quality cuts and small heat affected zone. To evaluate the effect of cutting parameters on surface roughness on SKD11, cutting parameters including power laser (P), cutting speed (v) and nozzle diameter (d), have been selected according to the Taguchi method. The result has revealed that the main factor affected to surface roughness was cutting speed with 45,73%, laser power at a ratio of 36,95% and nozzle diameter with 15,93%. A mathematical model of surface roughness function including power laser, cutting speed and nozzle diameter is formed by the orthogonal experimental design method though the experiental statistics. The outcome has proved that the effect of cutting speed is higher than the effects of power laser and nozzle diameter. Keywords: Laser cutting, SKD11, surface roughness (Ra), Taguchi |

Đối với ngành da giày, các hiệp định thương mại tự do không chỉ mang lại cơ hội gia tăng xuất khẩu mà còn thúc đẩy sự đổi mới, chuyển đổi chuỗi cung ứng và cải thiện chất lượng sản phẩm để đáp ứng các tiêu chuẩn quốc tế.

04/06/2025